Structure

There is no damage to the covering even after repeated opening and closing since the covering is fixed in two places on the ridge and on the drip tray.

The roof opening and closing structure expels hot air quickly

When the ceiling is opened, the interior space of the greenhouse is enlarged to promote convection

Sheath (vinyl)

Long-term thermal barrier coating film developed with state-of-the-art equipment and coating solution technology.

Maintains the best invincibility and warmth during economic life (2-5 years)

Optimal film suitable for crops with transparency and durability

Direct packaging possible without heat sealing up to 12m in maximum unfolded width

Switch

Easy to maintain as it is light

Maintaining the advantage of corrosion resistance with an opening and closing structure under the vinyl

By setting zones and automating them, it is possible to operate partial ventilation

Main function

The shading screen blocks (shading) strong light by reflecting the climatic characteristics of Vietnam to prevent internal temperature rise.

Diffuse screens scatter direct sunlight to maintain photosynthesis in plants

Prevents direct sunlight from raising the temperature of the leaves (leaf) of plants

Special feature

The S-Aluminum screen has excellent light reflectivity, so it has excellent shading effect in hot summer.

The diffuser screen uses a woven film to effectively disperse light.

Operated by automatic opening and closing method linked to smart farm.

Main function

Exhaust fan is installed for forced ventilation

When the fog system is operated, the internal humidity increases, and to prevent this, the exhaust fan is used at the same time to control the humidity.

Roof opening and closing cannot be used in case of rain, and forced exhaust operation through the side.

Special feature

As equipment with large air volume (43,000 ㎥/h), it is suitable for large greenhouses, etc.

High operating efficiency as a product developed with low power (1.1kw).

The wings are made of stainless steel to enhance durability.

Main function

Cool air supplied through the air conditioner is circulated inside the greenhouse

Minimize air deviation by circulating stagnant air

Special feature

Remarkably lower defect rate by using durable motor

Easy to install

Main function

Used for foliar fertilization necessary for crop growth.

Helps crop growth by automatically spraying pesticides and nutrients.

Special feature

The driving part can be applied to any rail structure of 25Ø, 32Ø, 42Ø

Even spraying can control even the underside of crop leaves

Auto-programmed drivetrain travel

Perfect durability through integration of pesticide hose and electric wire

Adjusting the spraying amount and spraying angle according to the growth of crops

Nozzle lock function for each stage

Minimizing noise with timing belts in the existing chain of the drive

Minimize A/S with perfect design

Main function

Lowering the internal temperature with a spray device using the vaporization heat cooling method.

Maintains humidity through internal micro-spray

Special feature

30HP/500L Air Compressor

With 80A/5HP atomizer or pump

OCR protection function (motor overload prevention)

Automatic valve function

Spray Time Air Time Auto Timer

Sequential spraying for each building

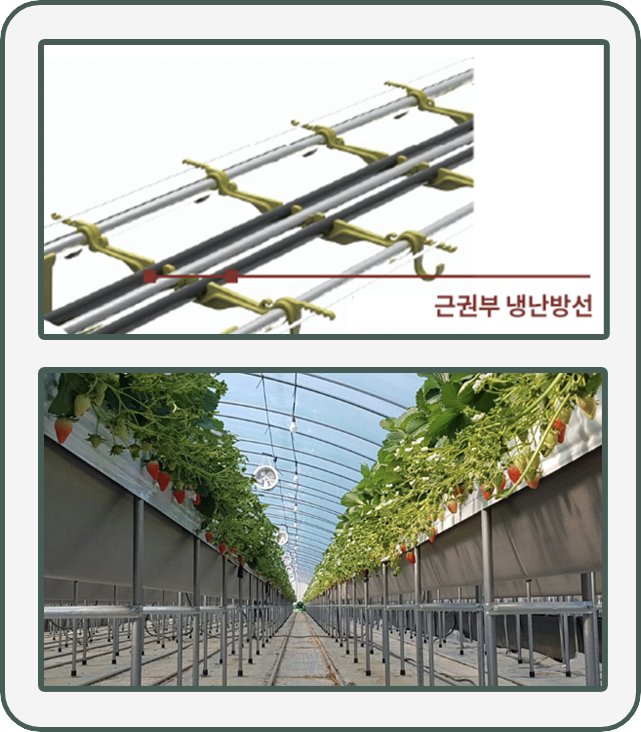

Main function

Sequential spray bed for each building is a basic facility for hydroponically growing strawberries, and it is possible to supply nutrients to crops and maintain moisture.

Artificially control the environment such as soil condition (EC, pH, temperature) when supplying nutrients through the nutrient solution.

Root zone cooling is a device that can control the temperature near the roots of crops, and is used by circulating cooled water.

Special feature

Expand the scale of the cultivation system by reducing labor and making light work.

The total yield increases as the harvest period is extended by 1.5 months compared to soil cultivation.

Cultivation is possible even in physicochemical soils with artificial bed facilities.

In the case of strawberries, the height of the fruit tree can be adjusted to increase labor productivity.

Main function

By cooling and supplying air outside the bed and root zone, the temperature inside the greenhouse is controlled and managed.

n particular, it is possible to secure the integrated temperature by lowering the night temperature and determine the quality of the fruit tree.

During the daytime, the fog system and exhaust fan control the internal temperature through the air conditioner at night.

Special feature

Hybrid air conditioner greatly saves energy by using double cooling structure

Manufactured inclusive of the advantages of existing air conditioning equipment (air conditioner, general air conditioner, evaporative cooling fan, etc.)

This equipment is a registered equipment for a patent (dual cooling method of vaporization-evaporation method, Patent No. 10-2138284).

Main function

A nutrient solution feeder is a mechanical device that supplies nutrients necessary for the growth of crops together with water

It can supply nutrients needed at the right time for growth, increasing nutrient efficiency, reducing labor and improving harvest quality

Nutrient solution automatic feeder enables EC management and pH control by mixing nutrients for precision agriculture.

Special feature

Securing reliability by using world-class EC and pH sensors and our own converters, solar radiation, soil temperature, and soil moisture sensors

The use of world-class parts such as motor pumps, valves and filters improves stability and precision.

Plantation can be divided into up to 12 zones (lines) and supplied..

Controls individual units such as motor pumps and solenoid valves precisely and in a balanced way by comprehensively calculating the data measured by various sensors and the conditions set by the user

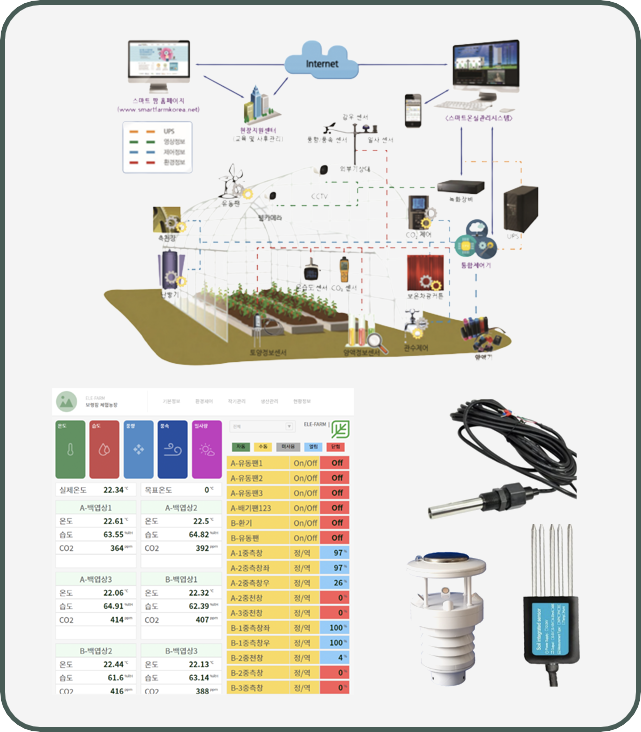

Main function

Collect internal/external environmental information through various sensors and use it for facility operation

Optimal greenhouse environment configuration through automatic control conditions of installed facilities

Enter cultivation, purchase, and sales data, and manage profit and loss information

Integrated and managed environmental information collection, control, and business management through an integrated and unified system.

Special feature

Apply the latest Node.js technology to Cloud Web-based Application

Constructed by adopting Korea (world) national standard technology (RS 485 modbus, etc.)

Configuration of automatic control of internal and external facilities through sensors such as external weather conditions and internal environments

Provides management system through agricultural ERP function along with environmental control

Multi-language is provided so you can choose your own language for operation